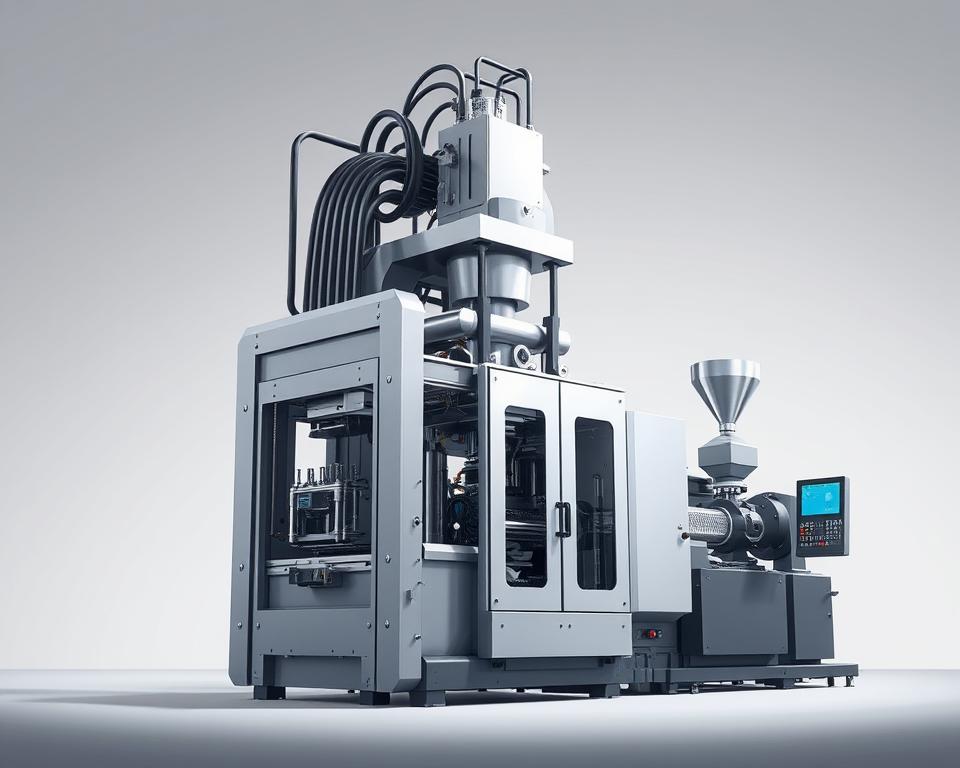

Guide to Finding Injection Molding Partners in China

Well, the major meeting has just concluded. your new project has the green light, time is pressing, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Naturally, you agree. It seems sensible at first glance. The cost savings can be huge. Yet your thoughts are already spinning. You’ve heard the stories, haven’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

Here’s the thing, though. Sourcing plastic mold company can be a calculated project. It’s simply another project with clear steps. And its outcome hinges on the approach you take. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Disregard those scary tales. Let’s walk through a real-world playbook for getting it right.

Initial Step: Prepare Your Information

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

What belongs in your RFQ?

Begin with 3D CAD models. They cannot be skipped. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. Add comprehensive 2D plans. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Don’t label it simply “Plastic.” Nor just “ABS.” Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. What’s the reason? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

Your supplier might propose substitutes, but you must set the baseline.

Lastly, add your business data. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? Tool style, cavity count, and unit cost are volume-driven.

Hunting for the Best Supplier

With your RFQ perfected, now, who do you send it to? Online sourcing is global but crowded. Finding suppliers is simple; finding quality ones is tough.

You’ll probably kick off on Alibaba or Made-in-China. They let you survey dozens of suppliers quickly. Treat them as initial research tools, not final solutions. Aim for a preliminary list of 10–15 potential partners.

But don’t stop there. Think about engaging a sourcing agent. They do cost extra. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. For a first-time project, this can be an invaluable safety net. Think of it as insurance for your project timeline.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Plus, ask peers for referrals. Ask other project managers in your network. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. bids begin to arrive. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

How do you do that? It’s a bit of an art and a science.

First, look at their communication. Are their replies prompt and clear? Can they handle detailed English exchanges? But the key: do they probe your RFQ? The best firms will question and suggest. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” Consider that a big green light. It shows they’re engaged and experienced. A supplier who just says “No problem” to everything is a walking red flag.

Afterward, verify their technical arsenal. Get their tooling inventory. Review examples of parts akin to your design. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Then comes the audit. This is not optional. Just as you interview hires, audit suppliers. Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

Transforming CAD into Real Parts

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. Together, you tweak the design for best manufacturability.

When you greenlight the DFM, they machine the mold. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. They are your moment of truth.

Expect T1s to need tweaks. That’s standard process. Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold in China parts arrive. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. It matches all specs, has a pristine finish, and works as required. This becomes the “golden sample.” You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Next up: mass manufacturing. How do you maintain consistency for part 10,000?

Implement a robust QC plan. Typically, this means a pre-shipment audit. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It relies on partnership-building. Treat them like a partner, not just a line item on a spreadsheet. Transparent dialogue, respect, and process discipline win. It’s a challenging project, no doubt. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’ve got this.